IN MOLD DECORATION

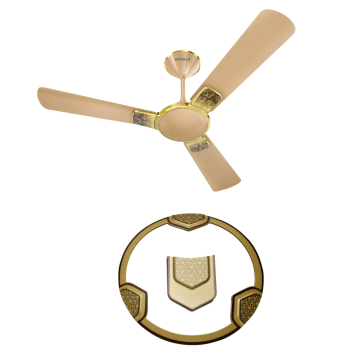

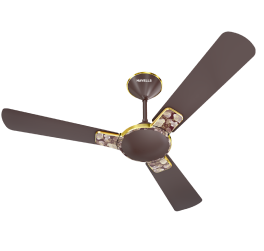

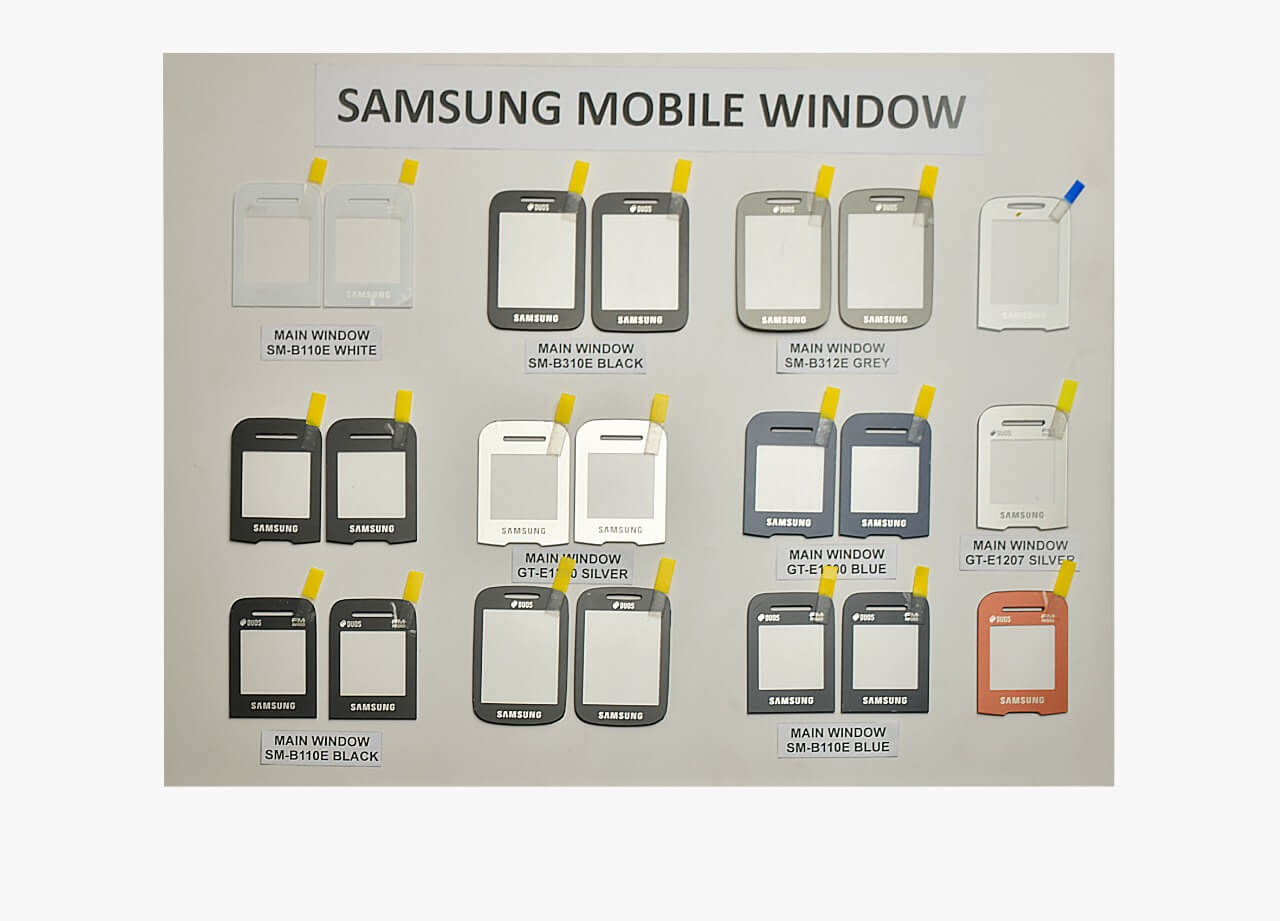

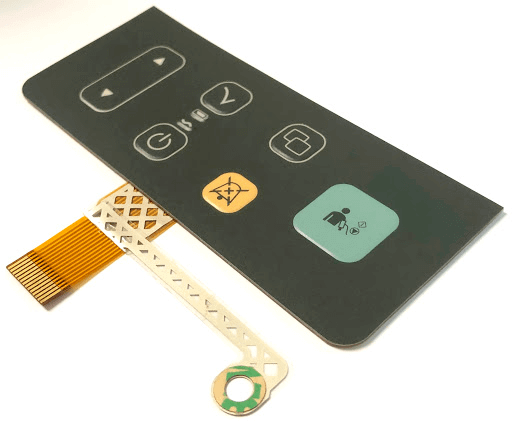

IMD/FIM is a process for decorating or labeling injection molded plastic parts or components during the plastic injection molding cycle.

In this process, a preprinted label or decorated appliqué film is inserted in the open plastic injection mold and held via vacuum ports, electrostatic charge, or other methods. The plastic injection mold is then closed, and the plastic resin injected to mold the part, encapsulating the decoration or label permanently within the finished injection molded part.